Welding MachinesINY-FLW-M Fiber Laser Welder Mold Welder

Introduction

The mobile laser welding system is suitable for welding small to big size molds, which is heavy and difficult to move.

Application Scope

Repairing all kinds of mold cracks, small holes, collapse, sealing edge and other tiny parts. It has irreplaceable advantages while compare with traditional welding like high accuracy rate, high speed, depth, strength, no holes after processing, can polish into shining surface after welding, especially suitable to repair mold which require polish.

- Description

- Product Data

The mobile welder laser welder main unit has wheels and workbench has mobile arm system, it can move by the side of molds and welding can be processed without unmounting the mold from the casting machine or the plastic injection machine, the mobile arm can stretch, turn and tilt to achieve focus range of up to 300mm allow welding in any position, deep cavity , items with complex geometries can be handled in an ergonomic working position due to the optional 360-degree swivel lens set of the laser focusing head.

Specifications

|

Specification/Model |

INY-FLW-M200 |

INY-FLW-M300 |

INY-FLW-M400 |

|

Laser Type |

Fiber |

||

|

Max. Output Power(W) |

200 |

300 |

400 |

|

Welding Depth(mm) |

≤2 |

≤3 |

≤4 |

|

Laser Wavelength (nm) |

1,064 |

||

|

Process Range (X-Axis, Y-Axis, |

200 x 100 x 200 |

||

|

Mobile Arm Travel Distance X-Axis, |

100 X 80 X 700 |

||

|

Pulse Frequency (Hz) |

≤50 |

||

|

Pulse Width (ms) |

0.2-20 |

||

|

Power Supply |

AC220V/50Hz |

||

|

Cooling System |

Water |

||

Feature

- Its unique structural design enables easy repair for various medium and large molds.

- Parameter adjustment is simplified using intelligent remote control, allowing for swift and straightforward operation.

- An optional CCD camera monitoring system facilitates precise positioning and observation, ensuring accurate welding.

- The red laser point indicator offers convenient positioning and ensures a stable fiber laser power output.

- This machine excels at welding in narrow positions and achieves accurate welding with deeper penetration.

- Boasting high-density laser energy and excellent laser beam quality, it ensures uniform distribution of energy in solder joints.

Advantages

Utilizing a fiber laser source, our machine offers precision welding with a minimum focus spot diameter one-third that of traditional YAG laser welding machines. Its outstanding photoelectric transformation efficiency ensures high performance while consuming just one-tenth of the power of conventional laser welding equipment. Individual Quasi-CW Fiber laser pulses can be modulated with analog control, enabling optimal temporal pulse shaping for any application. Due to its electro-optical conversion efficiency greater than 30% and its maintenance-free characteristics, its cost efficiency is far superior to conventional YAG lasers. The fiber lasers produce peak power ten times greater in pulsed versus CW mode and are ideal for the replacement of conventional flash lamp pumped YAG lasers used in spot welding, seam welding, and drilling. These compact units are more cost-effective than lamp-pumped YAG lasers due to their >30% wall-plug efficiencies and maintenance-free operation.

- Easy mold repair, save material, labor, and time costs.

- Superior quality laser beam, good welding quality, smooth, and high-quality appearance.

- Low operation cost, no consumables, maintenance-free, reducing production line debugging cost.

- Output fiber laser power stability, electro-optical conversion rate up to 30%, Its conversion rate is eight times that of YAG.

- Long lifetime, High photoelectric conversion efficiency, low energy consumption.

- fiber transmission provides better beam quality, highly efficient conversion, uniform welding spot, clean solder joints.

Application

mold & plastic industry, which adopts laser high energy focusing to effectively process tiny broken parts of molds.

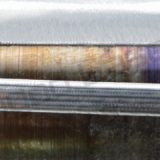

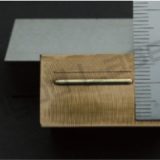

Samples

| Technology | Fiber Laser |

|---|---|

| Process | Welding |

| Processed Material | Metal |

| Output Power(W) | 200, 300, 400 |

| Welding Depth (mm) | 2, 3, 4 |

| Processing Dimension (X,Y,mm) | 200×100 |