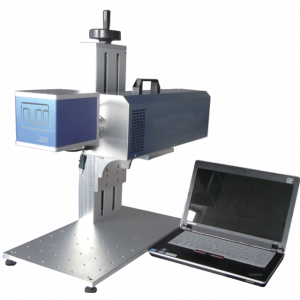

Cutting MachinesINY-CLC-CP CO2 Laser Cutting Closed Platform

Introduction

The INY-CLC-OP is a CO2 laser cutting and engraving machine, widely used in various industries, It operates in the mid-infrared wavelength range, around 10.6 micrometers, suitable to cut and engrave a wide range of non-metallic materials.

Application Scope

With its advanced features, it is the ideal choice for applications requiring fine cutting wide range of non-metallic materials such as PET, Acrylic, Aramid fiber, Leather, Paper, Wood, Rubber, Kevlar, Plastic, and other non-metallic film materials.

- Description

- Product Data

CO2 lasers are not suitable for cutting or engraving metals due to the low absorption of the CO2 laser wavelength by most metals. For metal cutting and engraving, other types of lasers like fiber lasers and Nd: YAG lasers are more appropriate choices.

Optional

- adoption of camera-positioning and automatic brim-seeking system.

- Motorized Z axis of the workbench

- Rotate device.

Specifications

|

Specification/Model |

INY-CLC-CP30 |

INY-CLC-CP60 |

INY-CLC-CP80 |

INY-CLC-CP100 |

INY-CLC-CP130 |

INY-CLC-CP150 |

|

Laser Type |

CO2 |

|||||

|

Max. Output Power(W) |

30 |

60 |

80 |

100 |

130 |

150 |

|

Process Range (X, Y) (mm) |

600 X 400 |

600 X 900 |

800 X 1400 |

800 X 1400 |

1000 X 1600 |

2500 X 1300 |

|

Cutting Speed (mm/min) |

0-25000 |

|||||

|

Power Supply |

AC100-220V/50Hz |

|||||

|

Cooling System |

Air or Water Cooling |

|||||

Feature

- Sealed Enclosure: The machine comes with a fully enclosed workspace, which minimizes the risk of laser beam exposure and provides a controlled environment for laser cutting operations.

- Enhanced Safety: The closed-platform design enhances operator safety by preventing direct contact with the laser beam and reducing the risk of scattered laser radiation.

- Improved Precision: The enclosed workspace minimizes external disturbances, ensuring consistent and precise cutting results.

- Reduced Material Contamination: The closed-platform design helps prevent dust, debris, and contaminants from interfering with the cutting process, resulting in cleaner and higher-quality cuts.

- Optimized Laser Performance: The controlled environment allows for stable laser performance, ensuring consistent cutting speed and accuracy.

- Versatile Material Compatibility: CO2 laser cutting closed-platform machines can cut a wide range of non-metallic materials, such as wood, acrylic, plastics, leather, fabric, paper, and more.

- Quiet Operation: The enclosed design helps reduce noise levels during cutting, creating a quieter and more comfortable working environment.

- Easy Maintenance: The sealed enclosure simplifies maintenance tasks, making it easier to clean and maintain the machine.

Advantages

- The enclosed workspace minimizes the risk of laser beam exposure and provides a controlled environment for laser cutting operations.

- Perform both cutting and engraving tasks, making them a cost-effective solution for a wide range of applications.

- Non-Contact processing feature reduces the risk of material damage and allows for delicate and precise work.

- High cutting speed, smooth corner, and high stability.

- Long Using Life: The machine is with long life using metallic-sealed-off CO2 laser.

- Good Cutting Effect: With excellent optical path design, produce a perfect focus spot, small thermal effect.

- Compatible with CorelDRAW, AutoCAD, Photoshop, and other software files

- Convenient data processing with dedicated laser cutting software. File formats include DXF, PLT etc. Interface is simple and friendly, effortless operation

Application

Crafts. Wooden artwork and gift box. Crystal nameplate. Certificate and agency badges. Sign engraving. Portraits and Pictures engraving, Organic glass. Double color board engraving. Leather decorating and cutting. Stone Engraving For parks. Automotive instrument panel, Automotive nameplate.

Samples

| Technology | CO2 Laser |

|---|---|

| Process | Cutting |

| Processed Material | Leather, Paper, Plastic, Rubber, Textile, Wood |

| Output Power(W) | 30, 50, 60, 80, 100, 130 |

| Cutting Thickness (mm) | 1, 2 |

| Processing Dimension (X,Y,mm) | 600X900, 600×400, 800X1400, 1000X1600, 2500X1300 |