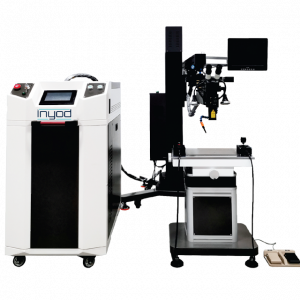

Welding MachinesINY-FLW-QCW Fiber Laser Welder Quasi Continuous Wave

Introduction

Quasi Continuous Wave (QCW) is a type of laser emission that lies between continuous wave (CW) and pulsed laser emission. In a QCW laser, short pulses are emitted with pulse durations ranging from a few microseconds to a few milliseconds, followed by a brief cooling period before the next pulse is emitted. Unlike traditional continuous wave lasers that emit a constant beam, QCW lasers produce bursts of laser energy. With QCW fiber laser source spot diameter is only one-third of the traditional YAG laser welding machine makes this machine suitable for precise welding.

Application Scope

It is used in mold & plastic industry, which adopts laser high energy focusing to effectively process tiny broken parts of molds. Such as: repairing all kinds of mold cracks, small holes, collapse, sealing edge and other tiny parts. It has irreplaceable advantages while compare with traditional welding like high accuracy rate, high speed, depth, strength, no holes after processing, can polish into shining surface after welding, especially suitable to repair mold which require polish.

- Description

- Product Data

Photoelectric transformation efficiency is extremely high. Its power consumption is 90% lower than traditional laser welding equipment which lowers operation costs significantly. It is exceptionally reliable, with almost no maintenance. Air cooling is used instead of water cooling. Machine dimension is 75% smaller than traditional YAG laser welding machine suitable to use in production line as a welding station or for automated integration.

Specifications

|

Specification/Model |

INY-FLW-QCW150 |

INY-FLW-QCW300 |

INY-FLW-QCW450 |

INY-FLW-QCW600 |

|

Laser Type |

Fiber |

|||

|

Max. Output Power(W) |

150 |

300 |

450 |

600 |

|

Welding Depth (mm) |

≤2 |

|||

|

Laser Mode |

Multi-Mode |

|||

|

Core Diameter (µm) |

50 |

|||

|

Laser Wavelength (nm) |

1,070 |

|||

|

Power Adjustment |

5-95% |

|||

|

Welding Speed (mm/sec) |

0~120 |

|||

|

Focal Diameter (mm) |

≤5 |

|||

|

Power Supply |

AC220V/50Hz |

|||

|

Cooling System |

Air |

|||

Feature

The QCW laser welding machine is an ideal choice for spot welding, seam welding and long pulse drilling. its electro-optical conversion efficiency greater than 30% and no maintenance etc. characteristics, the cost efficiency is far superior to the conventional YAG laser.

- Maximum Peak Power = 10x Average Power

- Outstanding Pulse Power/ Energy Stability

- Internal Pulse Generator/ Pulse shaping

- Wall-plug Efficiency >30%

- Pulse Duration* 0.05-50 milli second

- Single-mode or multi-mode

Advantages

Individual Quasi-CW Fiber laser pulses modulated with analog control to achieve the optimal temporal pulse shape or pulse train for any application:

- Multi-pulse for drilling

- Ramp up for pre-cleaning.

- Enhanced spike for high reflectivity materials

- Remove porosity or shrinkage pipe in center of weld.

- Ramp down pulse used for reducing cracking on crack sensitive materials

Application

It is used in mold & plastic industry, which adopts laser high energy focusing to effectively process tiny broken parts of molds. Such as: repairing all kinds of mold cracks, small holes, collapse, sealing edge and other tiny parts. It has irreplaceable advantages while compare with traditional welding like high accuracy rate, high speed, depth, strength, no holes after processing, can polish into shining surface after welding, especially suitable to repair mold which require polish.

Samples

| Technology | Fiber Laser |

|---|---|

| Process | Welding |

| Processed Material | Metal |

| Output Power(W) | 150, 300, 450, 600 |

| Welding Depth (mm) | 2 |

| Processing Dimension (X,Y,mm) | 200×100 |