ConsumablesINY-P-CR Ceramic Reflectors

Introduction

Inyod Ceramic Reflector (Ceramic Diffuse Reflector) main advantages are long lifetime. A porous alumina ceramic of 99.7% Al2O3 content, used extensively for long-life laser reflectors. This material is sintered at high temperatures to achieve a controlled porosity.

Application Scope

Inyod Ceramic Reflector (Ceramic Diffuse Reflector) are recently used in laser pump chambers.

- Description

- Product Data

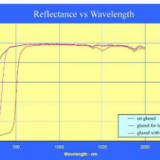

- Reflectance curve

- Surfaces can be sealed and coated with a solarization-resistant glaze to give high bulk reflectivity.

- 8% reflectance efficiency at 1000nm

- Reflectance efficiency exceeds 96% across the wavelength range 500-2000nm (see curve)

- Controlled porosity

- Good thermal conductivity

- High electrical resistivity

- Quality Assurance to BS EN 9001:2000

- Components up to 250mm long and 80mm wide/diameter manufactured as standard.

- Larger components are manufactured to development contracts.

- One-piece or split-cavity designs

- Prototype, batch, and volume production.

- Color: White

- Bulk density (fired), Mg/m3 :3.2.

- Porosity (apparent), % nominal:20

- Flexural strength (ASTM C1161, 3-point), MPa:150

- Thermal expansion coefficient 200-500C, 10-6/C 7.9 200-1000C, 10-6/C9.0

Efficiency: Wavelength, from independent tests conducted at the UK’s National Physical Laboratory

| Process | Consumables |

|---|---|

| Consumable | Ceramic Reflectors |