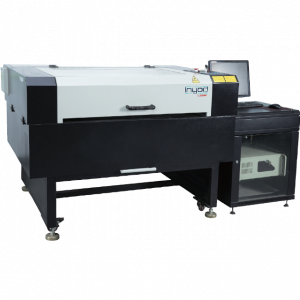

Engraving and Marking MachinesINY-UVM-OP UV Marking and Engraving Machine

Introduction

INY-UVM-OP UV Marking and Engraving Machine is a specialized laser system that utilizes an ultraviolet (UV) laser source to mark and engrave on various materials. UV lasers emit a shorter wavelength, typically in the range of 355 nanometers, making them suitable for marking on a wide range of materials, including metals, plastics, ceramics, glass, and more.

Application Scope

Whether you need to mark serial numbers, logos, barcodes, or intricate designs, the UV laser technology offers exceptional results on a wide range of applications

- Description

- Product Data

Experience the precision and versatility of our UV Marking and Engraving Machine, capable of delivering high-quality and permanent markings on various materials. Whether you need to mark serial numbers, logos, barcodes, or intricate designs, the UV laser technology offers exceptional results on a wide range of applications. Enhance your product identification, branding, and traceability with this advanced and efficient laser marking solution.

Specifications

|

Specification/Model |

INY-UVM-OP03 |

INY-UVM-OP05 |

INY-UVM-OP10 |

|

Laser Type |

Fiber |

||

|

Max. Output Power (W) |

3 |

5 |

10 |

|

Laser Wavelength (nm) |

355 |

||

|

Pulse Repetition Frequency (kHz) |

20~200 |

||

|

Marking Area |

110 X 110 |

||

|

Min. Character Size (mm) |

≤0.1 |

||

|

Engraving Speed (mm/sec) |

7000 |

||

|

Outline Dimensions (L, W, H) (mm) |

650 X 200 X 510 |

||

|

Machine Weight (Kg) |

< 100 |

||

|

Power Supply |

AC220V/50Hz |

||

|

Cooling System |

Water |

||

Feature

- High Quality UV laser source, to meet the requirements of long hours of continuous work.

- Low power consumption, long life of the laser, the power can be inflated to continue to use.

- Sealed metal cavity, laser life up to 20,000 hours.

- non-contact marking process, permanent marking effect, to meet the needs of significant quantities of industrial online or offline production.

- four large feet to ensure that equipment installation is stable and safe.

- Maintenance-free Operation

Advantages

Short wavelength, short pulse, high-quality light beam, high precision, and high peak power are the main advantages; therefore, the system has excellent application characteristics in special material processing fields to avoid thermal effect and increase processing precision obviously on various surfaces.

- High security: Designing enclosed laser optical path can effectively prevent the leakage of laser radiation.

- High stability: Increase the stimulated oscillation, reduce energy loss, good stability to ensure increased product quality.

- High speed, Perfect hardware, and software, with high-speed imported galvanometer, the marking speed can up to 7000mm / s, effectively improve production capacity.

- Good beam quality; Due to the small focus spot and the small heat affected area, especially suit for fine and precise marking.

- High performance: It has the characteristics of high photoelectric conversion efficiency, long service life of nonlinear crystal, stable operation of the whole machine, high positioning accuracy, high operation efficiency and no fading of marking.

Application

Metals: steel, aluminum, brass, copper, titanium, gold, etc.

Plastics: ABS, acrylic, polycarbonate, PVC, PET, nylon, etc.

Glass: Transparent glass, tinted glass, borosilicate glass

Ceramics: Porcelain, ceramic tiles, ceramic dishes

Electronics: PCBs, microchips, connectors, and components.

Medical Materials: Surgical instruments, medical devices

Rubber: Silicone, EPDM, neoprene, and rubber components.

Wood: Hardwood, softwood, plywood, and bamboo.

Paper and Cardboard: Packaging materials, cardboard boxes

Leather: Leather goods, shoes, belts, and bags.

Textiles: Fabric, leatherette, and synthetic textiles.

Plated Materials: Anodized aluminum, chrome-plated surfaces

Samples

| Technology | UV Laser |

|---|---|

| Process | Engraving, Marking |

| Processed Material | Ceramic, Glass, Leather, Metal, Paper, Plastic, Rubber, Textile, Wood |

| Output Power(W) | 3, 5, 10 |

| Processing Dimension (X,Y,mm) | 110×110 |