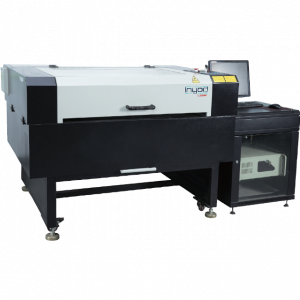

Cutting MachinesINY-FLC-PM Fiber Laser Cutting Precious Metal

Introduction

INY-FLC-PM, this advanced system utilizes fiber laser technology, known for its exceptional beam quality and accuracy, making it the perfect system for smooth and clean cuts with minimal heat-affected zones on precious metal materials

Application Scope

Precious metal laser cutting machine is specifically designed for precise and efficient cutting of precious metals, such as gold, silver, platinum, and other valuable alloys.

- Description

- Product Data

Precious metal laser cutting machine can be customized for imported laser source and various cutting heads available according to the jewelry industry needs. 9K-24K gold, 925 silver, sterling silver and other precious metals are highly reflective materials for laser beams. These metals have low laser absorptivity, strong reflectivity makes the cutting process impossible by ordinary laser devices. Our unique optical design, adding high-reflective laser isolator, makes our INY-FLC-PM series the best laser cutting machine for high-reflective materials.

Specifications

|

Specification/Model |

INY-FLC-PM1000 |

INY-FLC-PM1500 |

INY-FLC-PM2000 |

|

Laser Type |

Fiber |

||

|

Max. Output Power(W) |

1000 |

1500 |

2000 |

|

Cutting Thickness (mm) |

5 |

6 |

8 |

|

Laser Wavelength (nm) |

1070 |

||

|

Process Range (X-Axis, Y-Axis,Z-Axis) (mm) |

200 X 300 X 120 |

||

|

Cutting Line Width(mm) |

0.04-0.1 |

||

|

Pulse Frequency (Hz) |

1-500 |

||

|

Cutting Speed (mm/min) |

4800 |

||

|

X/Y-Axis Worktable Repeating Positioning Accuracy (mm) |

<±0.02 |

||

|

Z-Axis Positioning Accuracy (mm) |

<±0.02 |

||

|

Z-Axis Repeating Positioning Accuracy (mm) |

<±0.01 |

||

|

Power Supply |

AC220V/50Hz |

||

|

Cooling System |

Water Cooling |

||

Feature

With its advanced features, broad format support, and optional rotating shaft, our machine elevates your cutting capabilities to new heights, making it ideal for various jewelry and manufacturing applications.

- This system accommodates DXF, AI, PLT, and other commonly used drawing formats.

- Optional Rotating Shaft cuts easily bracelets, rings, and other jewelry items with the choice of a rotating shaft/

- Intelligent Height Tracking includes imported high-precision capacitive sensor, this machine offers full-time dynamic tracking of the plate height, automatic focus function of cutting head delivers precise cutting results.

- Superior servo motor drive and high-precision linear modules provides the machine swift and precise cutting up to 0.01mm.

- the benefits of a stable and long-lasting machine with minimal maintenance requirements, ensuring smooth and reliable operation.

Advantages

- Built-in Professional Dust and Dust Recovery Device: Our system features a unique sealed design, preventing the loss of gold powder and minimizing production losses. The gold powder recovery device efficiently collects gold powder, reducing wastage to a minimum.

- Non-Contact Cutting Process: The non-contact cutting process ensures the preservation of precious metal surfaces, delivering pristine finishes and preserving the material’s value.

- Special Optical Design for the Gold and Silver Jewelry Industry: Our system is equipped with a specially designed optical system, tailored to the needs of the gold and silver jewelry industry.

- Fine Cutting Width: Achieve precise cuts with a cutting width of 0.05-0.1mm, resulting in neat and smooth slits.

- Automatic Programmable System: Enjoy the convenience of our automatic programmable system, offering path optimization, cutting point optimization, multi-layer functionality, and layout features. This results in time and material savings during the cutting process.

- Small Size, Low Energy Consumption, and Easy Maintenance: Our machine boasts a compact size, low energy consumption, and easy maintenance, ensuring cost-effectiveness and efficiency in operations.

Application

The precious metal cutter laser is widely used in jewelry, watchmaking, dental, electronics, aerospace, and automotive industries to achieve precise cutting and shaping of precious metal components

Samples

| Technology | Fiber Laser |

|---|---|

| Process | Cutting |

| Processed Material | Metal |

| Output Power(W) | 1000, 1500, 2000 |

| Cutting Thickness (mm) | 5, 6 |

| Processing Dimension (X,Y,mm) | 200×300 |