Cutting MachinesINY-FLC-GCP Fiber Laser Cutting Glass Cutter Closed Platform

Introduction

The INY-FLC-GCP Fiber Laser Glass Cutting Machine incorporates advanced controllable glass cracking technology, combining heating and cooling to achieve both high-quality cutting edges and minimized micro-cracking issues.

Application Scope

With its advanced features, it is the ideal choice for applications requiring fine cutting, such as mobile phone covers, optical components, sapphire substrates, and more. Experience seamless and high-quality glass cutting with our innovative laser cutting solution.

- Description

- Product Data

The seamless laser glass cutting process involves several steps, including laser beam heating of the glass surface, increasing compressive stress without surface damage, cooling the cutting line surface with a coolant, and inducing sudden temperature changes to create higher tensile stress on the glass surface. With its advanced features, it is the ideal choice for applications requiring fine cutting, such as mobile phone covers, optical components, sapphire substrates, and more. Experience seamless and high-quality glass cutting with our innovative laser cutting solution.

Specifications

|

Specification/Model |

INY-FLC-GCP |

|

Laser Type |

Infrared picosecond |

|

Process Range (X-Axis, Y-Axis, Z-Axis) (mm) |

115 X 60 |

|

Cutting Thickness (mm) |

1.2 |

|

Max. Output Power (W) |

20 |

|

Laser Wavelength (nm) |

1064 |

|

Pulse Frequency (Hz) |

1-500 |

|

Pulse Width (picoseconds) |

10 |

|

Cooling System |

Water Cooling |

Feature

- Inyod Micro-Cracking Technology

- Process Glass thickness: 0.1-2mm

- Edge breakage size: <005mm

- Processing efficiency: 4s/pcs, 115*60mm, R5mm, DOL<50μm, T=7mm

- non-contact processing, less damage to materials, high cutting precision

- Layered three-dimensional cutting, used to cut non-strengthened and strengthened glass.

- Short laser single-point action time, small heat-affected area, no glass debris

- High-speed cutting with linear motor, high efficiency

Advantages

The next generation of laser cutting technology, where ultra-short pulse processing and precise visual positioning redefine the cutting experience. With our automated and efficient system, we achieve seamless cuts without compromising on edge quality. Elevate your cutting capabilities with our picosecond laser-powered solution, designed for stability, speed, and cost-effectiveness.

-

- Utilizing Picosecond Laser: Our innovative system employs a picosecond laser, enabling ultra-short pulse processing without heat conduction, resulting in smooth forefronts without edge collapse.

- CCD Visual Pre-Scanning & Automatic Positioning: Benefit from advanced CCD visual pre-scanning and automatic positioning, supporting multiple visual positioning features for precise and efficient cutting.

- Swift Cutting Speed & Consumable-Free: Experience fast cutting speeds and stable performance, while eliminating the need for consumables, optimizing cost-efficiency.

- Special Computer Software Control: Our system features automatic control through specialized computer software, allowing for seamless long-term operation.

- Equipped with Automated Processing System: Enhance productivity with our machine’s automated processing system, streamlining your cutting tasks for increased efficiency.

Application

Glass, sapphire, silicon wafer, silicon carbide, silicon nitride, aluminum nitride, gallium arsenide and other brittle materials cutting, shaped screen, silicon wafer.

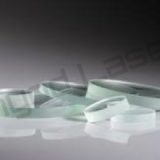

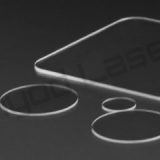

Samples

| Technology | Picosecond Infrared Laser |

|---|---|

| Process | Cutting |

| Processed Material | Glass |

| Output Power(W) | 20 |

| Cutting Thickness (mm) | 1 |

| Processing Dimension (X,Y,mm) | 200×300 |