Cutting MachinesINY-FLC-SP Fiber Laser Cutting Single Platform

Introduction

Compatible with a wide range of metal materials, including :

- carbon steel

- silicon steel

- stainless steel

- aluminum alloy

- titanium alloy

- galvanized sheet

- pickling plate

- aluminum zinc plate

- copper, and more

Application Scope

This versatile machine finds extensive application across various industries, including sheet metal processing, aviation, aerospace, electronics, electrical appliances, tube fittings, automotive, machinery, precision parts, shipbuilding, metallurgical equipment, elevators, household appliances, craft gifts, decoration, advertising, metal processing tools, and diverse cutting processing and manufacturing industries.

- Description

- Product Data

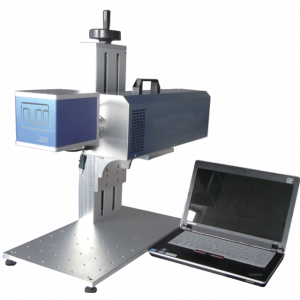

INY–FLC-SP The Fiber Laser Cutting Single Platform is a cutting-edge industrial machine designed to provide precise and efficient laser cutting capabilities for various materials. This advanced system boasts a single platform gantry structure, which enhances stability and ensures consistent cutting accuracy across the entire cutting area for a wide range of materials, steel, stainless steel, aluminum, copper, brass, and more, making it ideal for diverse industrial applications. The system incorporates high-power fiber laser technology that provides exceptional beam quality, energy efficiency, and minimal maintenance requirements.

The single platform gantry design offers increased rigidity and stability during the cutting process, resulting in superior cutting precision and repeatability.

Specifications

|

Specification/Model |

INY-FLC-SP500 |

INY-FLC-SP800 |

INY-FLC-SP1000 |

INY-FLC-SP1500 |

INY-FLC-SP2000 |

INY-FLC-SP3000 |

|

Laser Type |

Fiber |

|||||

|

Max. Output Power(W) |

500 |

800 |

1000 |

1500 |

2000 |

3000 |

|

Cutting Thickness(mm) |

2 |

3 |

4 |

5 |

6 |

8 |

|

Process Range (X-Axis, Y-Axis, |

500 X 500 |

1500 X 3000 |

1500 X 3000 |

2500 X 1300 |

4000 X 2000 |

6000 X 2200 |

|

Laser Wavelength(nm) |

1064 |

|||||

|

Pulse Frequency (Hz) |

1-500 |

|||||

|

Cutting Speed (mm/min) |

4800 |

|||||

|

X/Y-Axis Worktable Repeating |

<±0.02 |

|||||

|

Z-Axis Positioning Accuracy (mm) |

<±0.02 |

|||||

|

Z-Axis Repeating Positioning |

<±0.01 |

|||||

|

Machine Weight (Kg) |

4000 |

5000 |

6500 |

7000 |

8000 |

10000 |

|

Power Supply |

AC380V/50Hz/3Ph |

|||||

|

Cooling System |

Water Cooling |

|||||

Feature

Experience excellent cutting quality with our highly efficient metal cutting system:

- Superior processing quality and high efficiency with an easy-to-operate and maintain system.

- Enjoy smooth and fine edges or surfaces with minimal distortion.

- Cutting line widths as narrow as 0.05-1mm, ensuring high precision of up to 0.01mm.

- Conduct non-contact cutting and punching on metal or non-metal sheets and pipes.

- Higher cutting speeds, low operating costs, safe and stable operation.

- Automatically adjust the cutting height to prevent collisions.

- Experience high stability, a maintenance-free system, and a long service life.

Advantages

- This laser system boasts an extremely high cutting speed, surpassing CO2 laser machines with similar power by 2 times.

- Fiber laser source with stable performance, ensuring key components have a remarkable service life of up to 100,000 hours.

- This system achieves 3 times higher efficiency compared to CO2 lasers, promoting energy conservation and environmental protection.

- Power consumption of our fiber laser system is merely 20-30% of similar CO2 laser cutting machines.

- Optical fiber transmission eliminates the need for gas and reflection lenses, leading to significantly reduced maintenance expenses.

- With this system there is no need to adjust the light path, simplifying both operation and maintenance.

- Compact structural design provides flexible processing, adapting to various applications seamlessly.

Application

Applicable Materials: Our system is compatible with a wide range of metal materials, including carbon steel, silicon steel, stainless steel, aluminum alloy, titanium alloy, galvanized sheet, pickling plate, aluminum zinc plate, copper, and more. This versatile machine finds extensive application across various industries, including sheet metal processing, aviation, aerospace, electronics, electrical appliances, tube fittings, automotive, machinery, precision parts, shipbuilding, metallurgical equipment, elevators, household appliances, craft gifts, decoration, advertising, metal processing tools, and diverse cutting processing and manufacturing industries.

Samples

| Technology | CO2 Laser, Fiber Laser |

|---|---|

| Process | Cutting |

| Processed Material | Metal |

| Output Power(W) | 500, 600, 800, 1000, 1500, 2000, 3000 |

| Cutting Thickness (mm) | 2, 3, 4, 5, 6, 7, 8 |

| Processing Dimension (X,Y,mm) | 100×100, 110×110, 115X60, 200×100, 200×300, 500X500, 600×600, 600X900, 800X1400, 1000X1600, 1500X3000, 2500X1300, 4000X2000, 6000X2200 |