Cleaning MachinesINY-FLCL-CP Fiber Laser Cleaning Laser

Introduction

INY-FLCL-CP Fiber Laser Cleaning Laser is a specialized laser system designed for surface cleaning, paint removal, rust removal, and other cleaning applications, is a “green” cleaning technology.

Application Scope

Laser cleaning is highly effective on various metals such as steel, stainless steel, aluminum, copper, brass, titanium, and more. It can remove rust, paint, oil, and other contaminants from metal surfaces.

- Description

- Product Data

It utilizes the power of a fiber laser to generate a high-intensity laser beam, which interacts with contaminants, coatings, or oxides on the surface of materials, effectively removing them without causing damage to the substrate.

It is an innovative technology based on the interaction effect of laser and material, which is different from traditional mechanical cleaning methods, chemical cleaning methods and ultrasonic cleaning methods. It does not require any ozone – destroying CFC organic solvents, pollution-free, noiseless, harmless to the human body and environment, is a “green” cleaning technology.

Specifications

|

Specification/Model |

INY-FLC-CP200 |

INY-INY-FLC-CP300 |

INY-INY-FLC-CP500 |

|

Laser Type |

Fiber |

||

|

Max. Output Power(W) |

200 |

300 |

400 |

|

Cleaning Depth (mm) |

≤2 |

||

|

Laser Wavelength (nm) |

1,070 |

||

|

Cable Length (m) |

5M(Portable) |

||

|

Pulse Frequency(kHz) |

≤100 |

||

|

Power Supply |

AC220V/50Hz |

AC380V/50Hz |

|

|

Cooling System |

Air |

||

Feature

In recent years, as environmental awareness has grown, the global cleaning industry has faced significant challenges. Among the various cleaning technologies, laser cleaning stands out as an environmentally friendly solution.

- Non-contact Processing: Laser cleaning utilizes light energy without any mechanical contact, ensuring a gentle and non-abrasive cleaning process.

- Accurate Positioning: The laser beam can precisely target the material’s surface, making it suitable for cleaning irregular and hard-to-reach areas.

- Real-time Control and Feedback: The cleaning effect can be monitored in real-time using a CCD camera, and surface acoustic waves caused by the laser provide valuable feedback.

- Preserves Original Surface: With proper parameter settings, laser cleaning can selectively remove dirt and contaminants without damaging the original surface.

- Environmentally Friendly and Safe: Laser cleaning eliminates the need for harmful chemical cleaning agents, ensuring a pollution-free environment and providing safety for operators who require only basic protective clothing and face masks during operation.

- Effective Particle Removal: The laser’s adjustable spot size can effectively remove even small particles of pollution, including microscopic and smaller sizes.

Advantages

Embrace the advantages of laser cleaning technology for efficient and eco-friendly cleaning solutions, preserving surfaces while promoting sustainability in diverse industrial sectors.

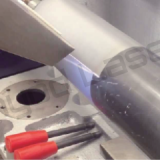

Application

Laser cleaning is highly effective on various metals such as steel, stainless steel, aluminum, copper, brass, titanium, and more. It can remove rust, paint, oil, and other contaminants from metal surfaces.

1. Precision mold cleaning

2. Selective paint removal for weld inspection

3. Removes oxides, oil, grease & production residues.

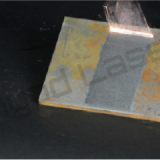

Samples

| Technology | Fiber Laser |

|---|---|

| Process | Cleaning |

| Processed Material | Metal |

| Output Power(W) | 200, 300, 400 |

| Processing Dimension (X,Y,mm) | 5000 |