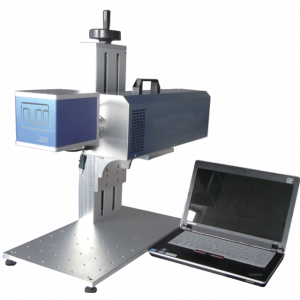

Welding MachinesINY-FLW-ALW Fiber Laser Welder Automatic Laser Welding

Introduction

Automatic Laser Welding Machine is controlled by an industrial PC, to align the welding spot over the working part, laser head can move in both the X and Y directions. This machine combines the precision of laser welding with the flexibility of multi-axis movement, allowing for efficient and precise welding in various applications.

Application Scope

Widely used in aviation, machinery, electronics, welding of automobile parts, hydraulic lever, gasoline filter, automobile tail gas sensor, solenoid valve and start motor stator, and seal welding lithium battery (mobile phone battery and energy battery), metallurgy (welding of silicon steel plate), motor blade welding electronic components, welding of (relay) electric apparatus industry, air conditioner motor rotor, leakage protector. communication, energy, chemical, automobile manufacture.

- Description

- Product Data

This Machine is equipped with a red laser spot for ensuring accuracy, safety, and efficiency during the setup phase, allowing operators to precisely position and align the workpiece for successful welding.

Specifications

|

Specification/Model |

INY-FLW-ALW200 |

INY-FLW-ALW400 |

INY-FLW-ALW600 |

|

Laser Type |

Fiber |

||

|

Max. Output Power(W) |

200 |

400 |

600 |

|

Welding Depth (mm) |

≤2 |

≤3 |

≤4 |

|

Laser Wavelength (nm) |

1,064 |

||

|

Process Range (X-Axis, Y-Axis, |

200 x 100 x 200 |

||

|

Camera System |

Red Pointer and CCD Camera |

||

|

Pulse Frequency (Hz) |

≤100 |

||

|

Focal Diameter (mm) |

0.1-2 |

||

|

Power Supply |

AC220V/50Hz |

AC380V/50Hz |

|

|

Cooling System |

Water |

||

Feature

Automatic Laser Welding Machine, equipped with innovative ceramic laser cavity and converging cavity design, setting a new standard for laser welding technology. This machine offers unique light beam mode selection and beam truing technology, ensuring exceptional output power and superior light beam quality.

- Long Lifespan: xenon lamp’s impressive lifespan of over eight million cycles

- Precise Power Control: The laser power supply allows optimal power management for diverse welding applications.

- Intuitive LCD Display: LCD display provides a user-friendly interface, making parameter management and control effortless.

- Advanced Software: Our software boasts digital filtering and high-speed control logic, ensuring stable and rapid welding.

- Ease of Use: Programming, debugging, and maintenance are made simple, streamlining the welding process, and reducing downtime.

- Enhanced Safety: The machine is equipped with automatic fail/safe protection, safeguarding both the operator and the equipment.

- Versatility: The system supports up to four axes, enabling 3D laser welding capabilities for versatile applications in various industries.

Advantages

integrated design that combines compact and elegant aesthetics with outstanding performance. With high output power, stable energy delivery, and excellent light beam mode, this welder sets new standards for laser welding technology. It promises simple operation, reliable performance, and extensive application possibilities, including multi-pulse capabilities for drilling.

- Easy welding of workpieces of diverse sizes and shapes, meeting diverse customer needs.

- Enables seamless execution of automatic or semi-automatic spot welding, butt welding, stack welding, sealing welding.

- Delivers superior weld quality, achieving flat and pore-free results. The welding frequency can be adjusted from 50 to 100Hz, with a remarkable wire speed of up to 18mm/s, significantly enhancing welding efficiency and overall weld quality.

Experience the seamless integration of performance and design with our series welder. Its impressive features, ease of use, and versatility make it the ideal solution for a wide range of welding applications, providing unmatched precision, efficiency, and weld quality.

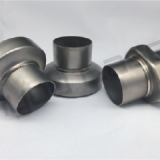

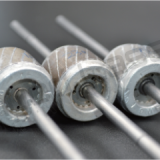

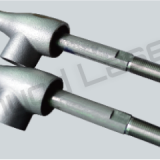

Application

Widely used in aviation, machinery, electronics, welding of automobile parts, hydraulic lever, gasoline filter, automobile tail gas sensor, solenoid valve and start motor stator, and seal welding lithium battery (mobile phone battery and energy battery), metallurgy (welding of silicon steel plate), motor blade welding electronic components, welding of (relay) electric apparatus industry, air conditioner motor rotor, leakage protector. communication, energy, chemical, automobile manufacture.

Samples

| Technology | Fiber Laser |

|---|---|

| Process | Welding |

| Processed Material | Metal |

| Output Power(W) | 200, 400, 600 |

| Welding Depth (mm) | 2, 3, 4 |

| Processing Dimension (X,Y,mm) | 200×100 |