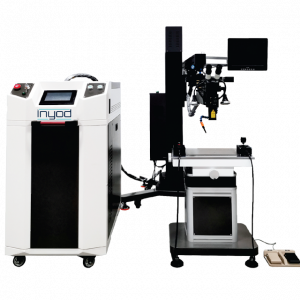

Welding MachinesINY-FLW-AP Fiber Laser Welder Automatic Positioning

Introduction

Laser welder automatic positioning machine has the feature of a laser welding machine that allows for automated and precise positioning of the laser beam on the workpiece. This automation eliminates the need for manual alignment and positioning by an operator, making the welding process more efficient and accurate.

Application Scope

Its features a highly sought-after welding technique, particularly in industries that require precise and efficient welding capabilities for complex and high-volume production tasks. This welder is used in highly efficient laser spot welding or seal welding of mobile phone shielding case, mobile phone metal shell, capacitor metal shell, metal shielding grid in computers, shaver blades, electronic connectors, and other electronic products.

- Description

- Product Data

The laser welder automatic positioning optimizes the welding process by streamlining setup, improving accuracy, and increasing productivity. As a result, this feature is widely used in industrial applications that require high-precision and efficient laser welding operations.

Specifications

|

Specification/Model |

INY-FLW-AP300 |

INY-FLW-AP400 |

INY-FLW-AP500 |

INY-FLW-AP600 |

|

Laser Type |

Fiber |

|||

|

Max. Output Power(W) |

300 |

400 |

500 |

600 |

|

Welding Depth (Mm) |

≤2 |

≤3 |

||

|

Laser Mode |

Multi-Mode |

|||

|

Core Diameter (µm) |

50 |

|||

|

Laser Wavelength (nm) |

1,064 |

|||

|

Power Adjustment |

5-95% |

|||

|

Welding Speed (mm/Sec) |

0~120 |

|||

|

Focal Diameter (mm) |

≤5 |

|||

|

Power Supply |

AC220V/50Hz |

|||

|

Cooling System |

Water |

|||

Feature

The AP laser welding machine is an ideal choice for spot welding, seam welding and long pulse drilling. its electro-optical conversion efficiency greater than 30% and no maintenance etc. characteristics, the cost efficiency is far superior to the conventional YAG laser.

- Maximum Peak Power = 10x Average Power

- Outstanding Pulse Power/ Energy Stability

- Internal Pulse Generator/ Pulse shaping

- Wall-plug Efficiency >30%

- Pulse Duration* 0.05-50 milli second

- Single-mode or multi-mode

Advantages

Fiber laser pulses modulated with analog control to achieve the optimal temporal pulse shape or pulse train for any application:

- Multi-pulse for drilling

- Ramp up for pre-cleaning.

- Enhanced spike for high reflectivity materials

- Remove porosity or shrinkage pipe in center of weld.

- Ramp down pulse used for reducing cracking on crack sensitive materials.

Application

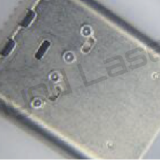

Its features a highly sought-after welding technique, particularly in industries that require precise and efficient welding capabilities for complex and high-volume production tasks. This welder is used in highly efficient laser spot welding or seal welding of mobile phone shielding case, mobile phone metal shell, capacitor metal shell, metal shielding grid in computers, shaver blades, electronic connectors, and other electronic products.

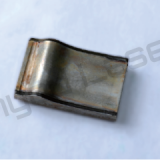

Samples

| Technology | Fiber Laser |

|---|---|

| Process | Welding |

| Processed Material | Metal |

| Output Power(W) | 300, 400, 500, 600 |

| Welding Depth (mm) | 2, 3 |

| Processing Dimension (X,Y,mm) | 200×100 |