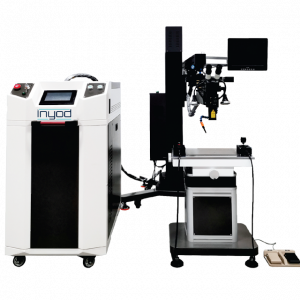

Welding MachinesINY-FLW-SPW Fiber Laser Welder Spot Precision Welder

Introduction

Fiber Laser Welder Spot Precision Welder, a cutting-edge solution that combines the power of fiber laser technology with unmatched spot precision welding capabilities. This advanced system sets a new standard for precision welding, offering remarkable accuracy and versatility for a wide range of industrial applications.

Application Scope

Our versatile laser welding machine finds primary application in the jewelry, dental, and hardware industries. Capable of processing a wide range of metallic materials

- Description

- Product Data

This advanced system sets a new standard for precision welding, offering remarkable accuracy and versatility for a wide range of industrial applications.

In just a matter of seconds, spot and seam welding’s are executed with unparalleled accuracy in the micron range, even in the most intricate and challenging areas. Achieving finesse and precision is unparalleled by any other welding method.

Specifications

|

Specification/Model |

INY-FLW-SPW200 |

INY-FLW- SPW300 |

INY-FLW- SPW400 |

|

Laser Type |

Fiber |

||

|

Max. Output Power(W) |

200 |

300 |

400 |

|

Welding Depth (mm) |

≤2 |

≤2 |

≤3 |

|

Laser Wavelength (nm) |

1,064 |

||

|

Process Range (X-Axis, Y-Axis, |

200 x 100 x 200 |

||

|

Camera System |

Red Pointer and CCD Camera |

||

|

Pulse Frequency (Hz) |

≤100 |

||

|

Focal Diameter (mm) |

0.1-2 |

||

|

Power Supply |

AC220V/50Hz |

AC380V/50Hz |

|

|

Cooling System |

Water |

||

Feature

By matching the parameters and shape of the laser pulses to each material, the laser generates a minimal heat affected zone, thus meeting the precondition for welding temperature-sensitive components. Another positive effect of the low thermal load of the two parts is that unwanted modifications of the joint by the welding process can always be avoided.

- High single-pulse energy. low heat, welding of gemstones or diamond.

- Long lifetime laser reflector made in U.K.

- High efficiency YAG crystal to ensure the best beam quality and energy.

- Installed a leather shutter of the welding chamber; Installed a safety shutter to protect against the laser emission. Safety class 1 laser product.

- Stable laser power supply ensures the system can operate 24/7.

- Using microcomputer-based LED touch screen to do human-computer interaction, intuitive interface, can set 50 sets of parameters, easy to operate.

Advantages

Experience the exceptional strength and durability of laser-welded joints, capable of withstanding high mechanical strain without wear, laser-welded joints exhibit remarkable temperature resistance and boast pore-free surfaces. With laser welding, post-processing is significantly reduced, and in many cases, eliminated, saving valuable time and resources.

- Minimal Heat Input: Say goodbye to distortion and damage to temperature-sensitive components. Our laser welding process involves minimal heat input, safeguarding delicate parts and preserving their integrity.

- Unmatched Precision: Our laser welding technology enables spot-accurate positioning and precise visual control through a stereo microscope, ensuring flawless welds, even in complex and intricate areas.

- Micro Welding Mastery: Experience the pinnacle of micro welding with weld seams smaller than 50 microns, all while maintaining high pulse-to-pulse stability, ideal for the most demanding micro-joining tasks.

- Filigree and Robust: Our laser welds are incredibly versatile, accommodating seam depths ranging from 50 microns to an impressive 2 mm, providing unmatched flexibility for various welding applications.

- Multifunctional Excellence: Discover the epitome of welding versatility with our technology, capable of spot, seam, overlap, and deposit welding, catering to diverse industrial needs.

Application

Our versatile laser welding machine finds primary application in the jewelry, dental, and hardware industries. Capable of processing a wide range of metallic materials, including gold, silver, platinum, titanium, palladium, K-Gold, stainless steel, and their alloys, it excels in manufacturing and repairing jewelry. Additionally, it precisely welds micro and heat-sensitive parts, such as nickel straps in batteries, hairsprings, watch components, and chip down-leads.

Samples

| Technology | Fiber Laser |

|---|---|

| Process | Welding |

| Processed Material | Metal |

| Output Power(W) | 200, 300, 400 |

| Welding Depth (mm) | 2, 3 |

| Processing Dimension (X,Y,mm) | 200×100 |